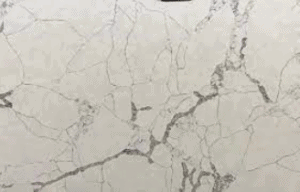

One of the most famous stones in the world has its origins in Italy, the Tuscany region – Aquan Alps.

The marble extraction goes back to the ancient Roman time, and the stone has been used to create statues to plaque the famous Romans baths or to be installed in the castles. Carrara quarry produces more marble yearly than any other place on earth.

Around 4 million tons of marble has been extracted annually, and around 13,000 employees have run the entire infrastructure on a daily basis.

The marble has been cut out from the mountain in different size blocks using 5 mm thick diamond wires. The blocks are then transported to the prefabrication sites undergoing various processes depending on their use.

There are two types of excavation: superficially and from the cave. The most expensive marble comes from the cave excavation due to the high cost involved during the operations.

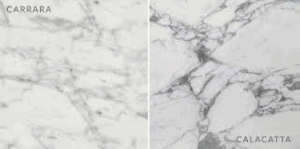

In 2019, 1,2 million tons of stone have been extracted from the mountain, and most of the stone has been exported to countries like China, the US, Germany and the UK (to name only a few) as well as throughout the world. The price of one slab of White/Bianco Carrara marble can cost up to £300 per square metre.

There are cases when Calacatta or Statuario marble can cost up to £9,000 per tonne. However, the entire existing mountain from where the Carrara marble family {with stones such a White/Bianco Carrara, Calacatta variety, Statuario, Arabescato} is evaluated to be worth £1 billion.

Most of the marble is prefabricated into slabs/tiles, and used to plaque walls or floors. In addition, it is estimated that , yearly, over 200,000 tons of mountain stone is fabricated and transformed into statues. These stones are well known for other uses such as fireplaces, tables, vases, etc.

Tuscany region passes the legislation which requires the quarries (down to only half of them still active) to transform at least 25% from the extracted stone into slabs, leaving around 75% to be categorised as wastage.

Giving the current wastage trend, there is a big chance that the Aquan mountain will transform into marble slabs.

There are currently many methods to rescue, restore and reuse the marble, even installed on the walls, floor, worktops, or baths. Modern technology works perfectly with an old school knowledge in order to transform the old marble into freshly new marble. So the old stone can be salvaged these days!!!

We have the capabilities to remove up to 5 mm (in extreme cases) from the top of the surface in order to expose healthy and unstained or undamaged marble. (around 90% of the cases), so this new face of the marble can be as good as a brand new purchased stone with no difference at all.

Further more, from this point of restoration, there are endless ways to finish the stone by giving it different textures from honed, polished and flamed to tumbled, satin, river or leather finish. This can be achieved using a variety of different methods in conjunction with tools, machineries and chemicals for the desired end result.

Part of the restoration process is also the application of seal that can ultimately make a big difference when it comes to protecting the stone from stones, etches and burns.