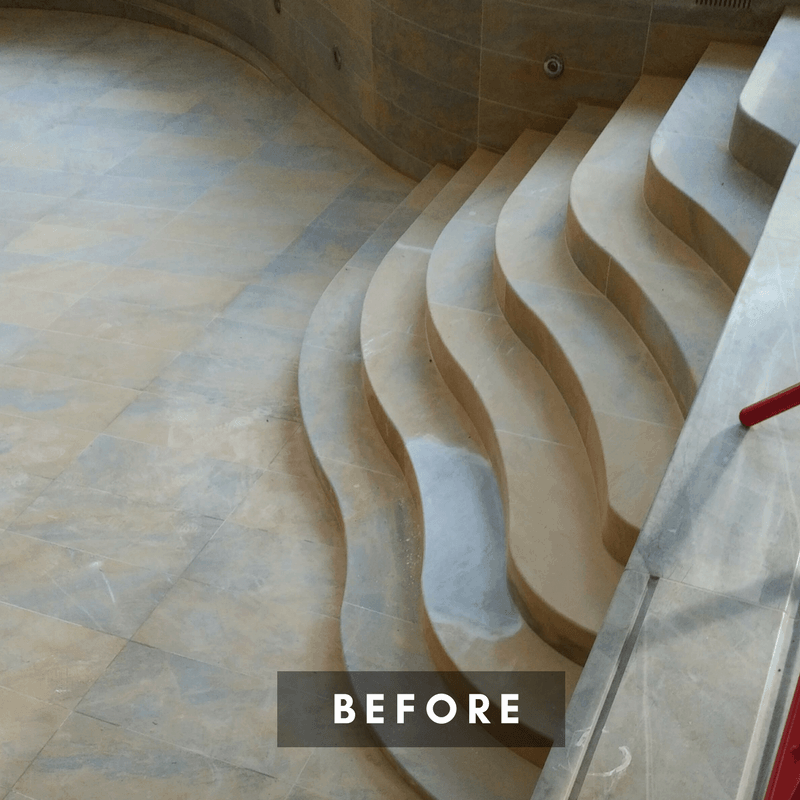

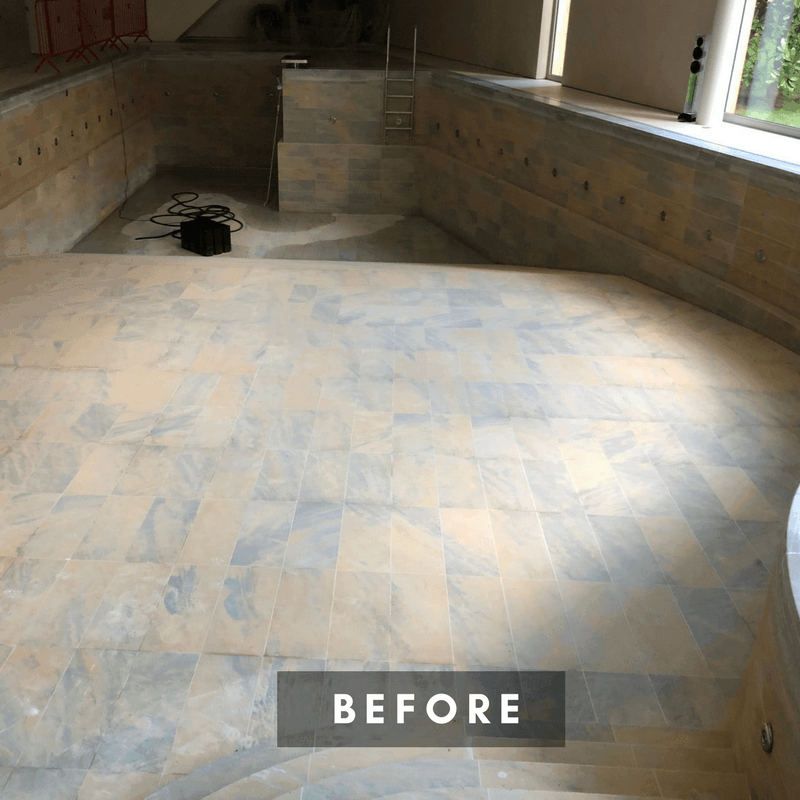

Swimming pool restoration

The basic steps of a marble swimming pool restoration will involve diamond cutting up to a few millimetres of the stone, to remove the damaged surface.

This being carried out by hand tools/polishers using towers for high-level access for the swimming pool walls and by heavy floor machinery to the swimming pool floor. Once this is completed, we will use several different grits of diamonds to polish the marble to a smooth finish throughout, closing the pours of the stone.

Finally, we will then apply the special formulated seal throughout the swimming pool stone.

The sealant is ‘high solids’ material, so it must be applied uniformly and worked over smoothly as unevenness do not disappear as with lower solid materials.

Also, the advantage of using rollers to the application is the mechanical mixing that occurs at the surface, giving extra security against dust causing weak adhesion by effectively stirring the sealant on the surface.

Although this is a generic description on the procedure of restoring swimming pools, these steps can vary from one swimming pool to another depending on few different factors such as, water control maintenance, UV, age and type of stone.

Our swimming pool seal will be specially formulated and customised depending on all the above aspects to ensure that the maximum and optimal protection is given to the stone.

Our recommendations:

To prevent dissolution of the marble lining, Ca++ ion concentration of the pool water must be kept at or close to the saturation concentration, at pH’s 7.2-.7.4 (ideal pool pH’s).

The temperature needs to be at 25 C, of approximately 0.0045 molar at a sodium bicarbonate concentration of 2ppm — the water test data supplied suggests that during 2017 Ca++ concentrations were generally too low to prevent erosion: on refilling the pool additional lime should be added to raise the Ca++ to approx. 500ppm when using sodium bicarbonate as a buffer at 2ppm.

During use, additional CO2 absorption from the atmosphere may require further lime dosing to maintain the concentration close to saturation.

Evidence of limescale formation or cloudiness due to lime precipitation will indicate that the Ca++ concentration is too high at that pH and temperature and must be corrected by pH reduction to the lower end of the ideal range.

-The water specifications should be carefully controlled and supervised by water management company.

-Our recommendations have an informative role and aren’t mandatory.

We’re using a revolutionary system, which is free of dust and easy to work with.

With this tool, we’re removing the stone damage, by grinding the stone about 2-3 mm from the top.